About Us

Discover Our Story

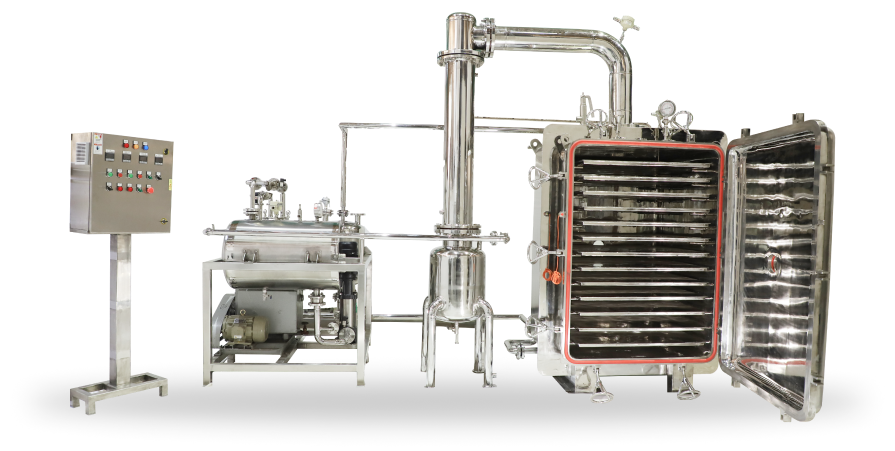

Vats and Vessels was established in the year 1980 as a proprietary company. In 2012 it was set up as a private limited company. Vats and Vessels (I) Pvt Ltd engineers to Pharmaceutical, Chemical, Food & Other Allied Process industries equipment. The company is equipped with wide range of equipments to cater to varied customers. The expertise gained over these years has emboldened Vats and Vessels (I) Pvt Ltd to innovate & create custom built equipments. Since its inception the company has grown steadily by adding to its product range, and today it has become a one stop buying place for its customers, virtually a supermarket, its growth has been aided by

Adherence to

Quality

Utilization of latest

Technology

Services to the

Customer

Competitive

Prices

Design, Manufacture, Supply & Installation of Process Machineries & allied Equipments for the Chemical, Pharmaceutical, Food, Paint & other allied Industries.

Bending & Rolling upto 25mm thk. Bending & Rolling upto 25mm thk. |

|---|

Facing : 2500mm dia.- Turning : 3000mm lg. Facing : 2500mm dia.- Turning : 3000mm lg. |

Cutting : Plasma cutting up to 16mm thk. Cutting : Plasma cutting up to 16mm thk. |

Welding : OXY/ACC, DC/ARC, AC/ARC, ARGON ARC (TIG) Welding : OXY/ACC, DC/ARC, AC/ARC, ARGON ARC (TIG) |

Handling Capacity :7.5 Ton Overhead Crane / 3 Ton Jib Crane Handling Capacity :7.5 Ton Overhead Crane / 3 Ton Jib Crane |

Longest Job Handled in SS : 22 meters Longest Job Handled in SS : 22 meters |

Largest Diameter Handled : 5 meters Largest Diameter Handled : 5 meters |

Highest Thickness Handled : 16 mm in SS / 50 mm in MS Highest Thickness Handled : 16 mm in SS / 50 mm in MS |

Grinding M/c Grinding M/c |

Sanders Sanders |

Rotofettle Flexible Shaft Grinders Rotofettle Flexible Shaft Grinders |

Flexible Shaft Grinders Flexible Shaft Grinders |

Pug Cutting M/c Pug Cutting M/c |

Process plants & equipments are designed and manufactured as per client’s specific requirements. Detailed design, layouts are prepared and detailed fabrication drawings are made for the plants and equipments. Designs & fabrication are in accordance to IS, BSS, ASME, TEMA & DIN Standards.

Production Planning. Inspection – Stage wise and Final. Testing - Hydraulic, Pneumatic, Dye-Penetration, Radiography, Ultrasonic, Chemical Analysis, Physical Testing.

Every incoming raw material is tested for chemical specifications and mechanical properties as per requirement by government approved laboratories. In house inspection is carried out at every stage of fabrication and appropriate reports are prepared. All necessary instruments and equipments are available for dimensional inspection, pressure testing, speed & current measurement. Every equipment after inspection is accompanied by the complete test report along with ‘As Built Drawings’.